Dust Collection

by Anthony Wong • February 4, 2016 • How To • 1 Comment

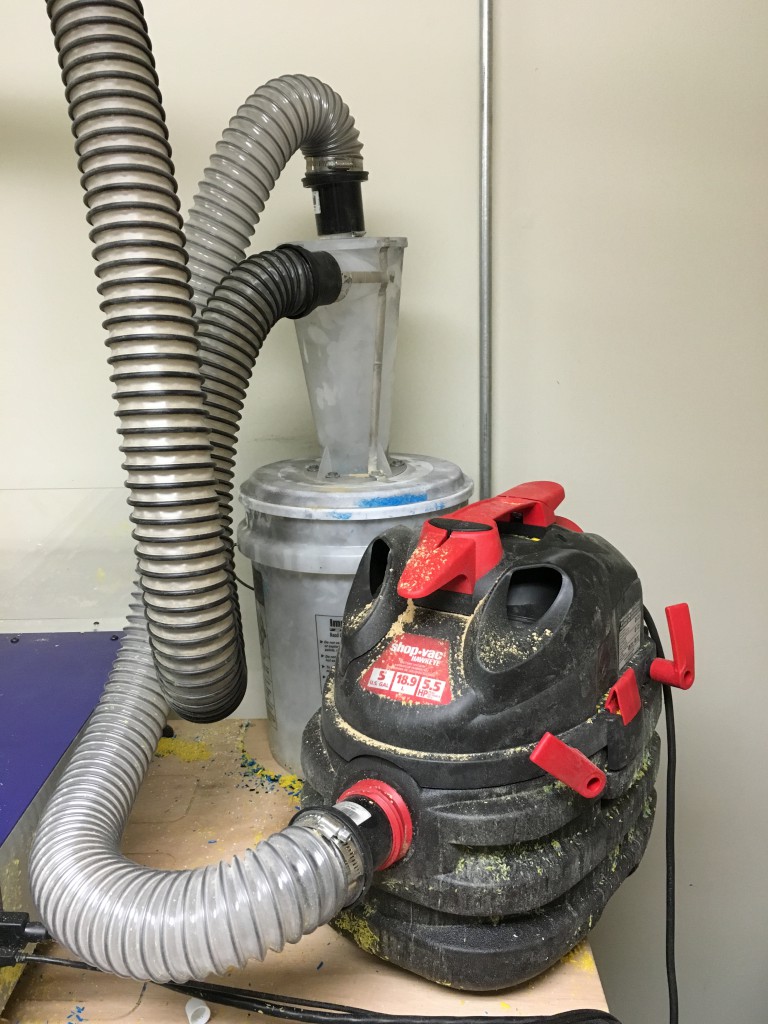

I’ve spent a bit of time, in other blog posts, talking about various parts of the production setup we use to cut Handibot parts. One big piece of using CNC routers in production environments that I haven’t touched on is dust collection. CNC routers are dust making machines – if it’s not making dust and chips, we’re not making money. Recently we’ve been playing around with cyclonic separators in our dust collection system. A cyclonic separator is a cone-shaped device that you install between the vacuum and the tool. The separator uses the air flow from the vacuum to suck up the chips generated by the tool, but the trick is that it separates the chips from the air flow so that they never get to the vacuum. They’re kind of hard to explain without a diagram of the air flow, so if you’re scratching your head, I’ll refer you to the wikipedia page.

One reason people use cyclonic separators is that they can help save your air filters. The dust and chips fall out in the separator and cleaner air goes through the vacuum filter. We mostly generate large plastic chips that don’t cake onto the filters so this isn’t really a big problem for us, but if we spent more time cutting materials that generate fine dust (like MDF or garolite) we would probably appreciate the filtration benefits of the separator that much more. In addition to saving the filter, it would also help save our lungs by giving us a second chance to catch the fine dust. However, the main benefit we’ve found for them is that they’re easier to empty. Rather than taking apart our ShopVac and dragging the base to the dumpster, we can pop the top off the separator and carry a 5 gallon bucket with a convenient handle. Given that on a busy day we can fill up a 5 gallon bucket in no time, the convenience factor isn’t inconsequential. We use a Dust Deputy, which is pretty pricey, but thankfully, cyclonic separators are a really old technology and thus fall into the public domain. You can search the internet for plans for DIY versions. My favorite are the ones made out of a traffic cone.

We use the cyclonic separator with the Desktop Max tools for cutting Handibot parts. If you end up getting a separator, it would also work well with the new dust foot we’ve designed for the Handibot 2.0. I’ll try to get a picture or video of the new dust foot posted soon.

That’s really incredible producing the technology to separate the chips from the dust! Very cool product and information.

Denis Sully

http://www.powertoolquest.com