Fabricating Your Future: Handibot Attends the US FabLab Network Symposium

by Sallye Coyle • April 16, 2014 • News • 0 Comments

First…it’s probably not a secret, but the Convention Center at the Maritime Institute close to BWI airport is a great place to hold a meeting. If you like boats and ships, you will be in heaven. It includes a small bar where, one evening, I set up the Handibot on a table and ran it. It did cause a bit of a stir, even though I didn’t carve my initials in any of the tables.

The members of USFLN (www.USFLN.org) are mostly Community Colleges whose missions include serving the Community by having open hours to use the digital fabrication equipment, serving Entrepreneurs by making digital fabrication equipment open to them, and Education in the form of classes for credit, for Continuing Education and workshops. During the Ignite sessions, where a representative from the USFLN member gets 5 minutes and 15 slides to talk about their program, there was a theme…about 50% of the community members who utilize the FabLabs are artisans, there have been successful prototypes developed at many of the FabLabs, and students (high school through college) are thriving and loving their experiences in the FabLabs. There was another refrain: “We used our ShopBot to make this.”

The Handibot was on display during the days of the meeting. It was a bit of a crush, but a Handibot, two computers and some samples fit on a small table. Talk about being able to take CNC machining out to the world! It gave more than a few participants ideas about what to put into their mobile FabLabs and Maker Spaces in Libraries.

The Digital Fabrication equipment in a Fab Lab is not limited to CNC machining. Laser cutting, vinyl cutting, electronics, 3D printers are all part of the equipment inventory. Training FabLab gurus, educators and community members to use the equipment successfully is an ongoing process. Helping educators see the value of using Digital Fabrication in Design Thinking, and aiding them in developing meaningful curricula is a theme that a number of groups are pursuing. A few websites to examine are 100kSchools, Digital Fabrication Learning Center, Fab Foundation, TIES. Creating local support groups and having a repository of success stories are important functions of each of the on-line communities.

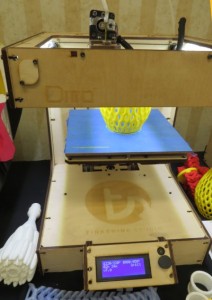

Deciding which Digital Fabrication Equipment to put in a school or maker space is always a relevant topic. Who will use the equipment, what is your budget, what do you want to do, what populations are you trying to serve, what is the time frame for being able to actually produce something. Digital Fabrication is not just 3D printing, although the idea of 3D printing has engaged more people in the possibilities than any other type of equipment. And, based on the other vendors at the USFLN show, there are a lot of choices for 3D printers. Cost, service contracts, material type and cost, quality, reliability and time to print an object are all considerations when choosing a 3D printer.

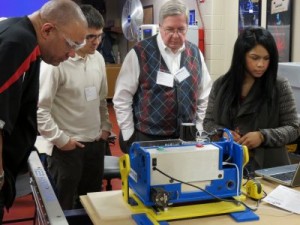

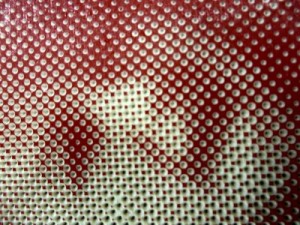

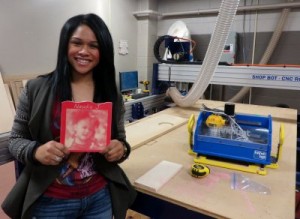

Having the opportunity to see several types of Digital Fabrication tools in action allowed educators to evaluate which kind of Digital Fabrication equipment to purchase. In less time than it took to print the vase above, two experienced FabLabbers, Andrea Lane and Nick DiGiorgio, created a file for the Handibot that went from photograph through to half tones to finished product reminiscent of Lichtenstein and Ben-Gay dots. It’s a different process and outcome, yes, but consider the flexibility. Check out the April 2014 blog on 100kSchools for more examples of Digital Fabrication equipment side by side. The information on the jig we used to hold the board in place can be found on both 100kSchools and the March blog on this, the Handibot site.

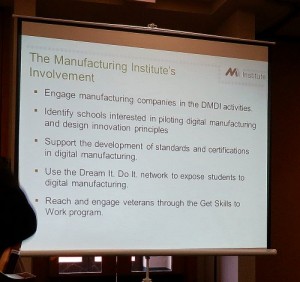

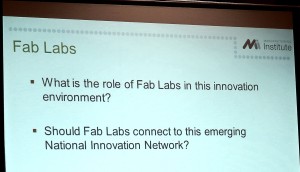

The Community Colleges are tasked with Workforce Development, and often house job training, job retraining, and, in some cases, facilities to be be able to manufacture products that have been prototyped in the FabLab or Maker Space. At a lunchtime talk, Gardner Carrick, VP of the Manufacturing Institute spoke of programs aimed at manufacturing in the US.

The last morning of the Symposium, we moved to the FabLab at the Community College of Baltimore County. We used the PRS alpha ShopBot to demonstrate Aspire 3D CAD/CAM software, then put the Handibot on the big ShopBot table and Andrea set up to run her own photo project.

Thank you to the organizers of the USFLN symposium, Judy Loar and Ken Burch, and to Kelly Zona and Molly for being great hosts at the Baltimore Fab Lab.