Collaborative Product Development in an Open Source Hardware Environment: Responses to Some Specific Customer Questions

by Ted Hall • February 9, 2015 • News • 1 Comment

A couple days ago, I received an email from potential Handibotter, Tim Deagan. Tim asked a couple of useful and challenging questions about the timing of our upcoming development releases for Handibot. Because I think a lot of people have similar questions, I asked him if it would be okay to share them in a blog post here and to provide what answers I could.

Tim noted: “I’m incredibly excited that I’ve finally saved up to buy a Handibot, but I’m hesitant based on the target dates for the next releases as discussed in the blog. Late February 2015 for v1.1 and possibly June for v2.0.”

Tim wondered:

- It seems like I’d be making a mistake in purchasing prior to the 1.1 release. It’s even a bit of a nail biter as to whether I should knock myself unconscious until June and hope the 2.0 is out. However, I’m a software developer, so I’m painfully familiar with the difference between target dates and actual release dates. Ultimately, I would love to make my decision based on price/features.

- I know there is a limited amount of information you can provide at this time, but is there any insight you can provide about:

- Level of confidence in v1.1 feature set?

- Price changes for v1.1?

- Level of significant difference anticipated in the v2.0 release?

- Level of price change anticipated (sub $500, sub $1000, over $1000) compared to the current developer edition?

- Level of confidence in v2.0 release target date (50/50?)

- Again, I recognize the impediments to answering any or all of my questions, but I’m really eager to buy a Handibot, but don’t want to do so and the following week have painful buyer’s remorse (or worse have to sell mine in a couple months to step up to the unbelievably cooler v2.0). My budget is tight, so if the price differential will be greater than a couple hundred, I’m better off buying now.

Let me take Tim’s questions a bit out of order (note that my next blog post continues this discussion in a more general way):

1. I’d say that we are 80% certain that all of the described updates will be included in the Handibot v1.1 and that we will make the target date for release. The upgrades (except for the proximity switch changes*) are fully compatible with v1.0 by purchasing an upgrade kit from us, or by DIY from the updated plans.

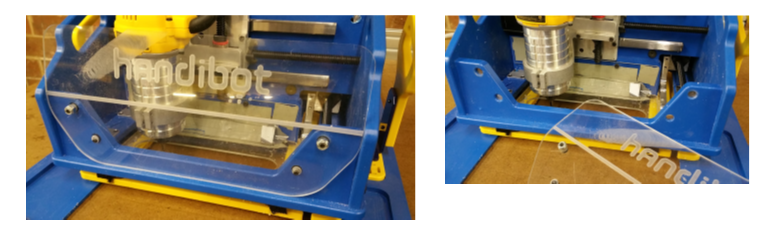

Prototype of new “V-Neck” front for Handibot v1.1. Front piece is removable and held in place by strong magnets.

2. & 4. We are not expecting a price change with v1.1.

While it is our intuition that a tool with the physical capabilities of a Handibot (with today’s type of motion-system hardware components) may eventually be priced from $1000 to $2000, our current focus is not on price reduction. We are more interested in having a tool that allows full exploration of what capabilities are most useful for this type of platform and figuring out how to best exploit them. Once we understand that, we’ll go after compromises that will help with price-saving adjustments we can pass along to purchasers.

As consumers, we have come to expect very impressive price reductions as product types are scaled and volume-methods come into play. These phenomena are particularly obvious with electronics. You can certainly see it happening with 3D printers. However, with subtractive digital fab tools — tools that we hope to use with a wide range of materials and with high precision — there are physical forces in play that require (at least in terms of how we currently conceptualize their workings) power, rigidity, and aggressive mechanical cutting. To deliver these, we use motions systems (rails and bearings); motors and drive trains (steppers and screws); and routers, spindles, and cutting tools. These components represent the expensive items in a Smart Tool. On the positive side, a hundred years of industrial evolution makes the current component solutions highly reliable and widely available. But what this history also means is that the components have already been commoditized and costs for them are unlikely to become radically lower, even with larger volumes.

That said, slightly better pricing on motors, screws, rails, and bearings may help us reduce the price of v2.0 by $100 to $200. It is our thought that v2.0 will be more of a consumer version and less of a developer version, but that this change in functionality will be primarily because we will have shifted to the new, more universally accessible, FabMo motion control platform (available for earlier versions, too).

We have also contemplated more limited-use and lighter-duty versions of the Smart Tool concept that might be considerably less expensive (say, $500-$800), but such tools would be more specialized, intended for certain types of light cutting or machining, and not equivalent to a Handibot in versatility or range of use.

5. Tim’s “50/50″ is a pretty good estimate for us hitting the v2.0 target date. We would really like to have a working version ready to show at the Bay Area Maker Faire in May, so we are motivated. But, it may be a bit more of a stretch to be production-ready and able-to-ship at the start of June.

3. We do expect a significant difference in Handibot version 2.0. It will ship with the FabMo motion control platform hardware and software. We have not yet fully solidified potential physical changes. We will be sharing experiments and prototypes on this as we get the v1.1 release behind us. But conceptually, the idea is to open Handibot up for even more robotic activities. This will probably mean a work-bay that is entirely open at the front. We refer to this as our “horseshoe-shape” base concept. The “V” shaped neckline of v1.1 is a step in this direction. At the moment, the thought is to preserve the existing Handibot footprint (except for the front bar or the base) to make it backwardly compatible with existing accessories. However, we expect to use a more rigid material for the base (aluminum being a possible option).

Physically, Handibot v2.0 should have essentially the same capabilities as v1.0 and v1.1. That’s because we expect no change in the basic motion or drive systems. We are still contemplating the footprint/work-area of future tools. Along these lines, I hope to soon post some pictures of a larger, custom Handibot experiment. It’s a tool with a longer front to back work area — you’d have no problem working across a 2’×12’ with this one. So yes … we are puttering around with this and certainly believe a change in work-area is worth considering.

But with the offset-drive design for the base axis that we currently use, it is difficult to go beyond 6 inches of cutting-width (the Handibot’s X axis) and still preserve the rigidity that allows us to do aggressive cutting — because increasing leverage on the far side of the drive can allow “racking” of the orientation when there is too much force on the cutter. I should also indicate that we generally favor the current 6″x8″ (150x200mm) work area as it seems a good compromise between a tool that can be moved around and a minimally useful envelope. So fundamentally, I imagine that we are getting close to a final commitment to the current size or something close. Sticking with the same work area means that even though v2.0 is likely to have a modified design, owners of v1.0 and v1.1 will already have the major components of the next tool. It will be interesting to see what type of upgrade-ability we can create.

These are my best shots at answers to Tim’s questions. I appreciate that I’m leaving more than a few unknowns — but in fact, Handibot is a work in progress. One of the disadvantages of the forthright nature of the Handibot experiment is that it does put us all in the situation of not being quite sure how the tool will develop. Even more difficult is knowing what recommendation to give Tim, or others, about whether or when to buy into the project. We aren’t trying to sell it in the “sales” sense. We are encouraging those who can make use of a good little CNC — and more importantly, those who are interested in participating in the evolution of something that becomes more than just CNC — to join us.

* For the proximity switch upgrade to v1.0: This is looking like it is going to take a bit of fussy work involving drilling and some grinding or filing. At the moment we are thinking in terms of offering a kit with the updated parts and some basic plans and suggested methods. Then, we hope a few Handibotters will jump in with details of their experience with the upgrade and perhaps some more specific instructions about the process as it worked for them — maybe a video or two.

Pingback: Collaborative Product Development in an Open Source Hardware Environment: Thoughts … | Handibot Blog